Robotics – International University Rover Challenge

Overview:

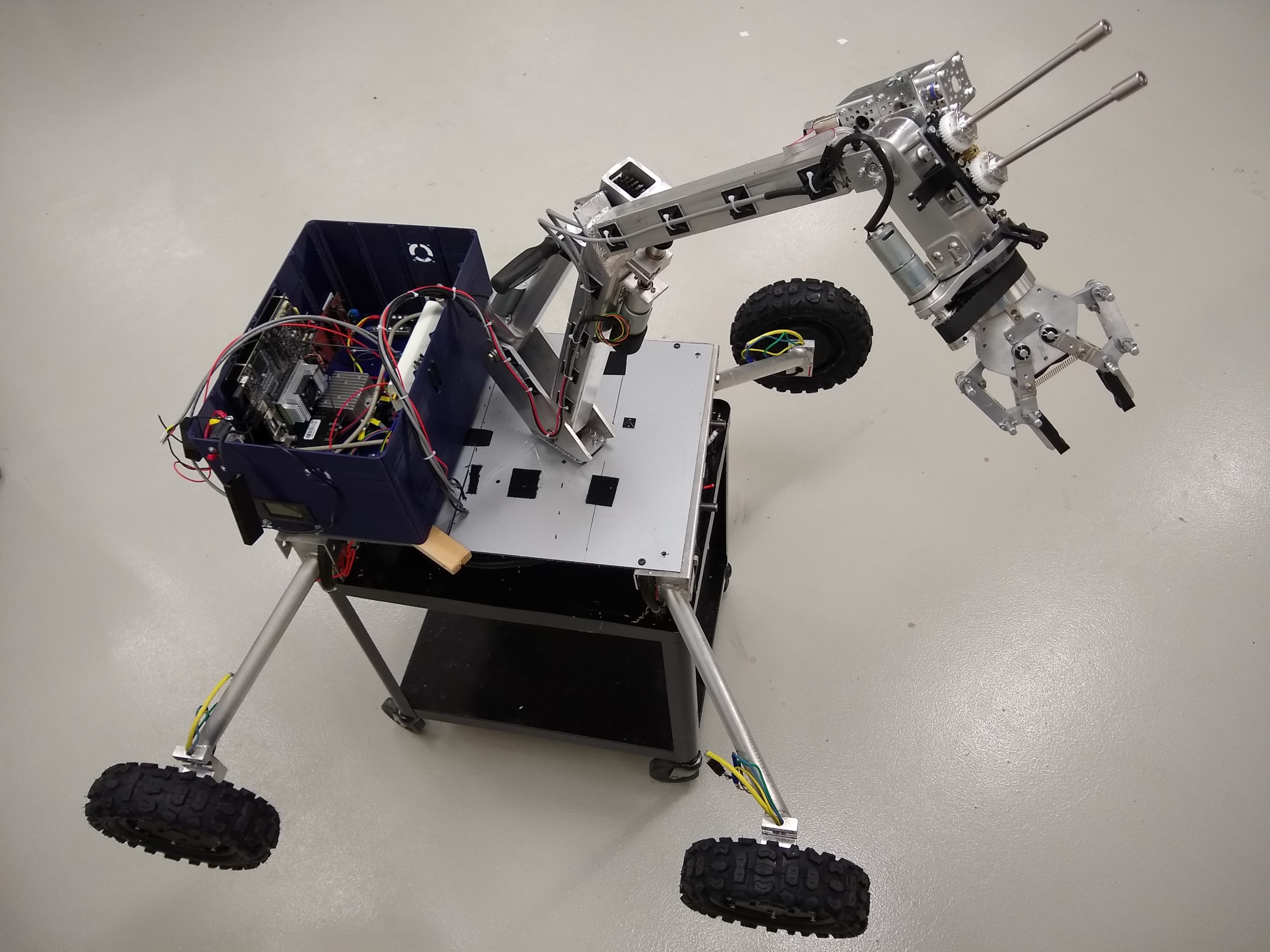

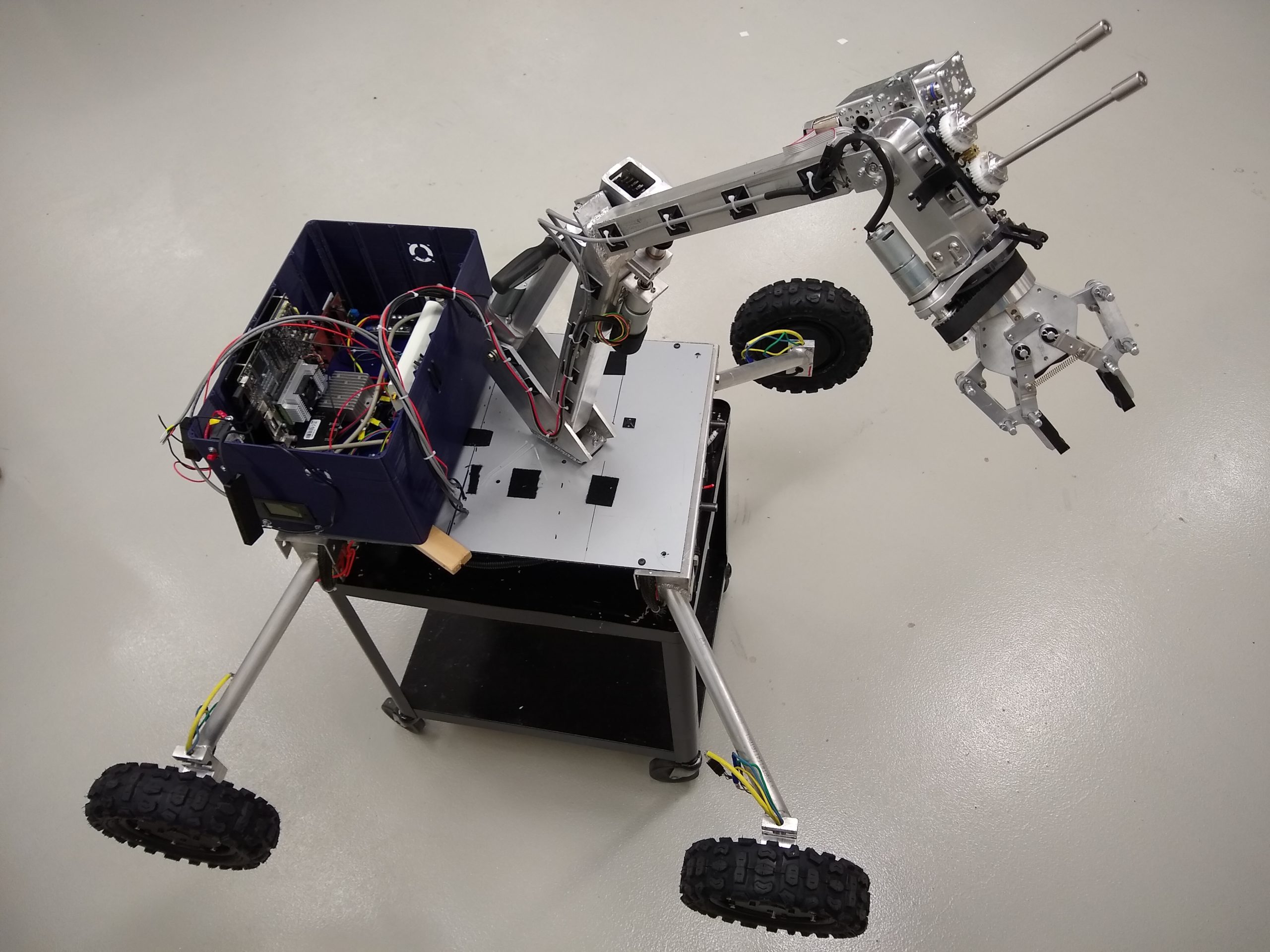

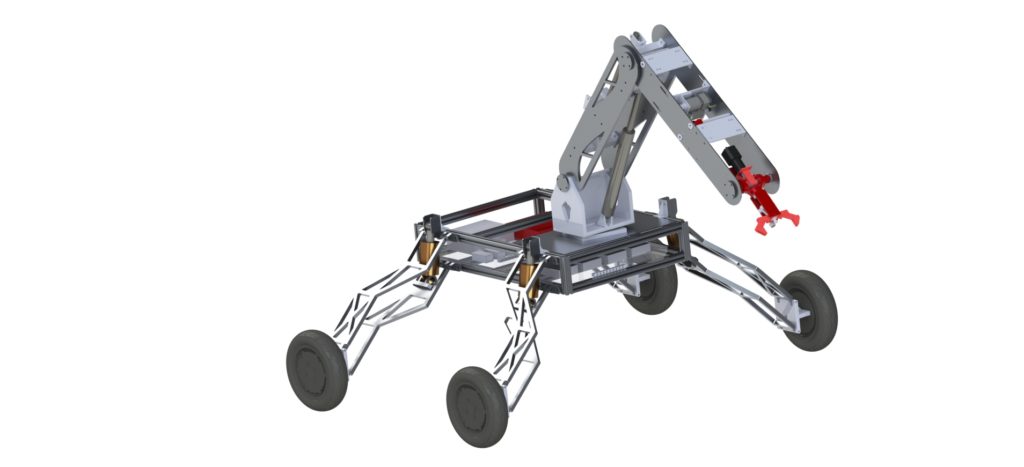

As former Vice President of the University of Alaska’s Robotics team, I’m proud to showcase the capabilities of the rover I worked so hard to bring to life, the “Iceberg”. The size of the club varied throughout my time there, but grew as large as 30 individuals.

For reference, we competed in the University Rover Challenge, a multinational contest.

The Robotics team was divided into teams dedicated to the rover sub-systems, I led the electronics team, which included about 5 members.

Electrical and Electronics:

My primary area of contribution. I provided the team with oversight as a team lead for 3 semesters. During my time with the robotics team, I redesigned and rebuilt the robot from the ground up, including all sourcing of individual parts.

The brain of the robot, an Artificial Intelligence capable “Jetson TX2” computing module. The main drive motors were repurposed from two Segways. In order to control them a pair of Dual Channel Brushless DC Motor Controllers were employed. These motor controllers were chosen for their robust performance characteristics and low cost. The hall effect sensors in the brushless motors interface with the motor controller to manage wheel speed and position feedback.

The power for the rover is provided by a 48v 720 watt-hour lithium-ion battery, providing ample power for each competition task. Five cameras faced in various directions give the driver sufficient visibility from a remote operating station. These provide multiple close-ups of the end effector and wide-angle views of the arm and rover, these camera streams can be broadcast in full HD via a set of 900MHz Ubiquiti radios which carry video streams and rover commands.

There were diverse power requirements on the rover that required buck converters from 48v to 24v, 12v, and 5v. We employed rotary encoders in various locations to prevent the robot from overextending and causing damage to itself.

For the electronics setup, I personally sourced items from Jetson, Pololu, Mouser, DigiKey, Molex, Trossen Robotics, Robo-teq, Servocity, Actuonix, Banebots, OMC Stepper Online, RobotShop, Ubiquiti, and various smaller vendors.

Software and Autonomous Navigation:

The Base-Station runs a custom graphical application built with wxPython for viewing rover camera streams, and monitoring and controlling the rover. It features a navigation system to display the position of the rover in real-time from transmitted GPS coordinates, and a configurable control system, enabling operation of the rover with a pair of gamepad controllers.

One shortcoming of the rover design during my time with the club was the Autonomous Traversal capabilities. Eventually the rover will be able to use the onboard GPS and Accelerometer/Magnetometer to precisely determine its position and orientation. It will then use OpenCV to analyzes the image and depth data from a stereoscopic camera to detect obstacles and hazardous terrain, and identify competition markers.

Conclusion:

This concludes a brief overview of the rover as designed for the 2019 University Rover Challenge at the Mars Desert Research Station. I appreciate your interest in my part of the project! I’d be happy to answer any questions that you have about the robot.

Senior Design Project

My project was an Arduino microcontroller based GPS tracking system. It was designed to be a versatile anti-theft device for deployment in automotive and recreational vehicle settings.

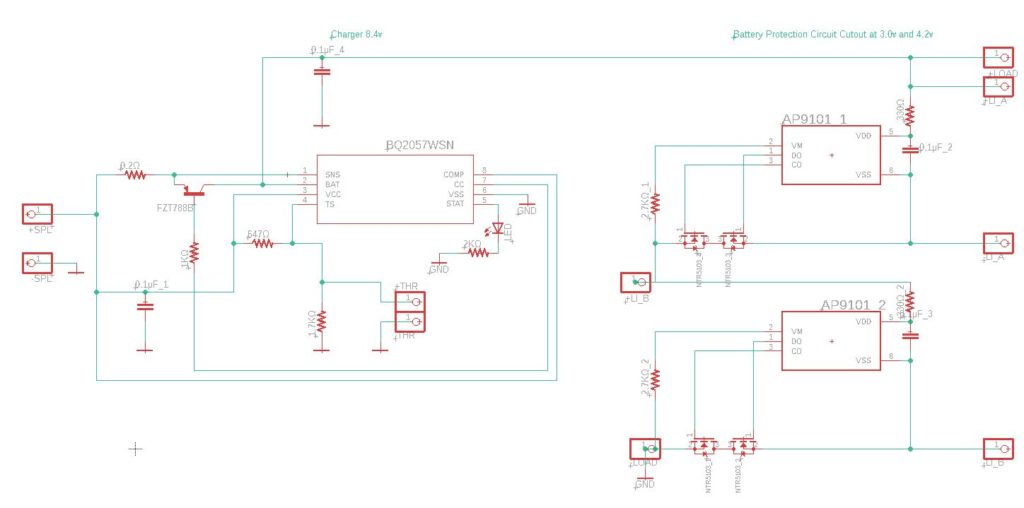

The following is a schematic of the battery charging and protection circuitry that I designed for this project:

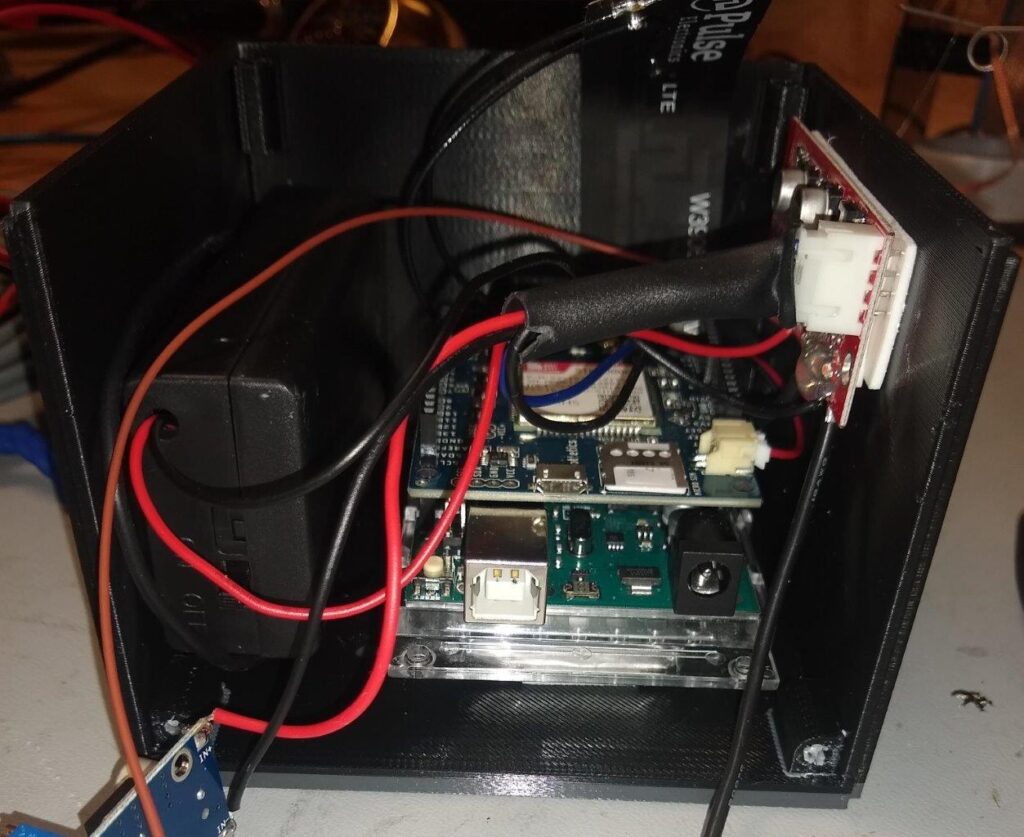

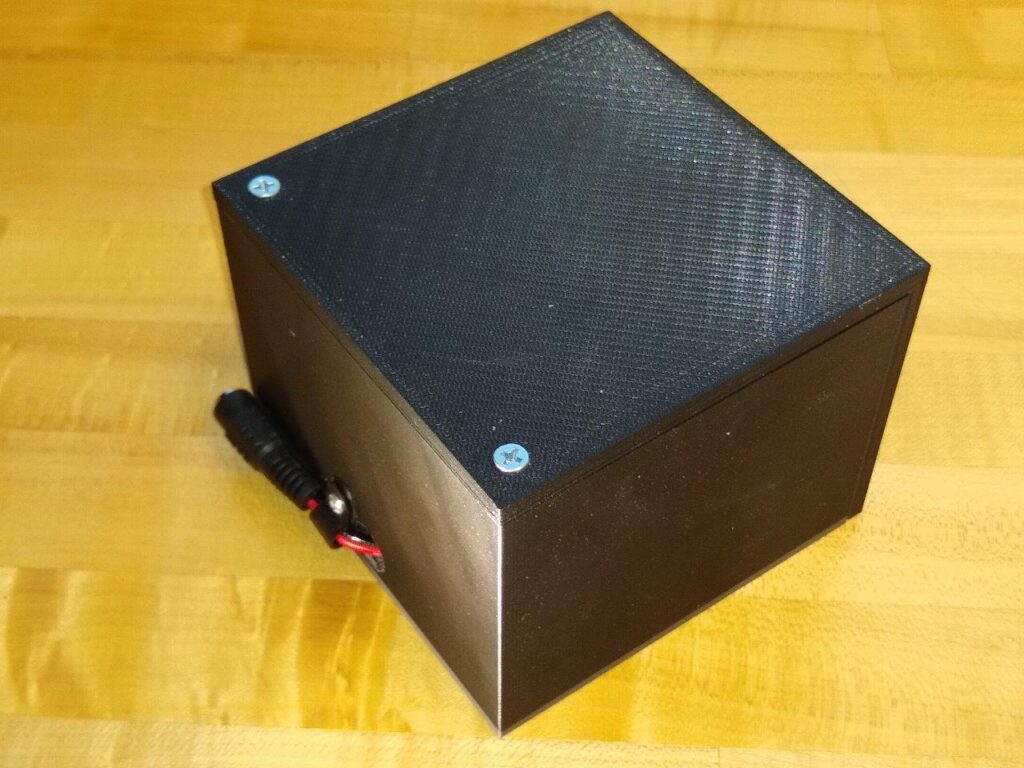

The open and closed “black box”, the functioning tracking prototype:

This project was a fun adventure into the world of gps tracking, and helped me further refine my C++ coding skills, as well as building some “low power” IC implementation knowledge. Designing and building a PCB to control the onboard power was easily one of my favorite parts of my undergraduate experience. I was the team lead for the project, which allowed me to have greater control over the direction that we took with the project, and helped me build my leadership and management skill set.